Call us on +44 (0) 01288 354 454

A revolution in water filtration — The best screen filter protection for your pump! The Seradisc® Filter massively outperforms the traditional options, giving much improved screening with less blockages, easier cleaning and can be fitted to most pumping systems.

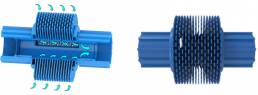

The Seradisc® Filter is better by design – The Seradisc’s unique design has increased the screen surface area, diffusing the flow and reducing the velocity at any given point. This helps prevent vortexing and subsequent cavitation. The design also allows for the discs to be squeezed together or expanded apart, giving you total control over the particle filtration grades.

The parallel structure of the discs in the Seradisc® screen interfere with the circular formation of a vortex forming. The outer surface area of the Seradisc® filter screen is extremely large, so the velocity of water flow at any given point is relatively low. This dramatically reduces the likelihood of a vortex from forming from any point on the outer surfaces.

Superior Results

"Had the Seradisc system for 2 years, not one problem, not one pump breakdown. This system is so good, it's amazing, it's very cheap, economical, doesn't wear out, non corrosive, the perfect system!" – Customer quote – Charlie from Mineshop Cottages, Cornwall.

Features & Benefits

The unique design of the filter discs enables a high flow area whilst maintaining exceptional structural strength. See the full list of features that make the Seradisc® an essential part of your water delivery system.

- Variable grade screening – The Seradisc filter includes 16 discs but can accommodate up to 42 to filter particulates from 4mm down to 0.1mm

- Easily adaptable for shallow submersion – The Seradisc is adaptable to very shallow applications via break-off tabs allowing use in water levels as low as 130mm

- Easy cleaning – The Filter is easily cleaned by simply brushing or rinsing debris off

- Multipurpose 2” BSP adaptor – Each Seradisc kit comes with 2 BSP adaptors which are multifunction by way of a knockout inner disc

- Strong and durable construction – The Seradisc is manufactured to high standards with durable compounds allowing the filter to be lightweight yet strong and long lasting while avoiding any degradation.

- Modular & Expandable – For increased capacity or larger pipe work the Seradisc may be utilised in many configurations

- Seradisc protection cage and float – picture with seradisc inside – An integrated cage and float increase the versatility of the Seradisc by enabling the filters to be floated in the clearest portion of water below floating debris and above the water bed.

- Manifolds for high volume pumping application – Simple manifolds can be manufactured to suit most applications depending on flow rates and particular application requirements. NOTE – WPT do not manufacture these manifolds – however, discounts are available for larger orders of filters and ancillaries. Please contact WPT should you require assistance with large project applications or opportunities.